Warehouse Temperature Compliance

Everything you need, all in one place

To comply with GDP and GMP, warehouses must demonstrate strict control over storage conditions. This involves validation, mapping, monitoring, calibration, and thorough documentation.

TekTroniks is an ISO certified, UKAS accredited company providing compliant temperature and humidity monitoring systems, calibration, and temperature validation (temperature mapping), for the warehouse and logistics sector.

Tailored for the warehouse industry

Real-time Monitoring

Wireless warehouse temperature and humidity monitoring made smarter, real-time insights, full compliance and zero stress.

UKAS Accredited

Temperature Mapping

ISO 17025 certified temperature mapping for warehouses, cold stores, trailers and temperature controlled areas.

UKAS

Calibration

Laboratory and on-site calibraton for Warehouses.

Validated

Installation

IQ-

Installation Qualification

OQ-

Operational Qualification

PQ-

Performance Qualification

What makes Tek Troniks the right choice for warehouse and logistics compliance?

We are uniquely suited for your compliance needs, supporting pharmaceutical, food safety, and cold chain logistics. We provide the essential tools (mapping, monitoring, and calibration) that ensure customers have precise, auditable data to consistently meet GxP regulatory requirements.

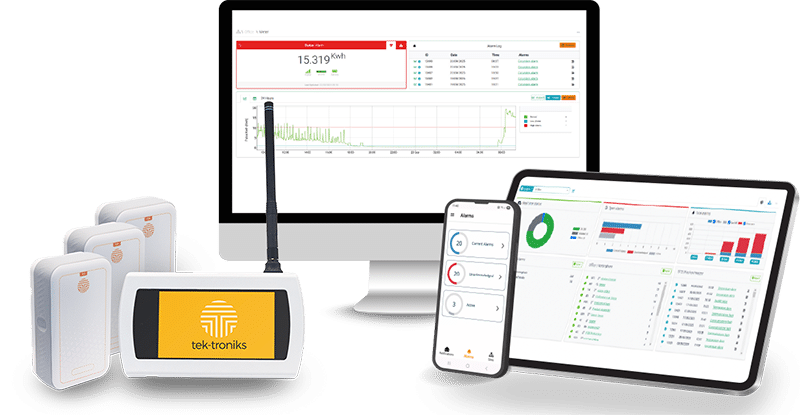

Easy, Wireless and Secure

Reliable automated warehouse temperature monitoring

Simplifies compliance

GDP & GMP

Alerts

Email, SMS & Push notifications

Wireless Sensors

Robust long range wireless sensors, Simplifies installation.

Sensors

Temperature, humidity, door events and much more.

Alarm escalation

Ensures the right people get the right alerts - fast.

7 Year battery life

install and forget.

Compliance ready

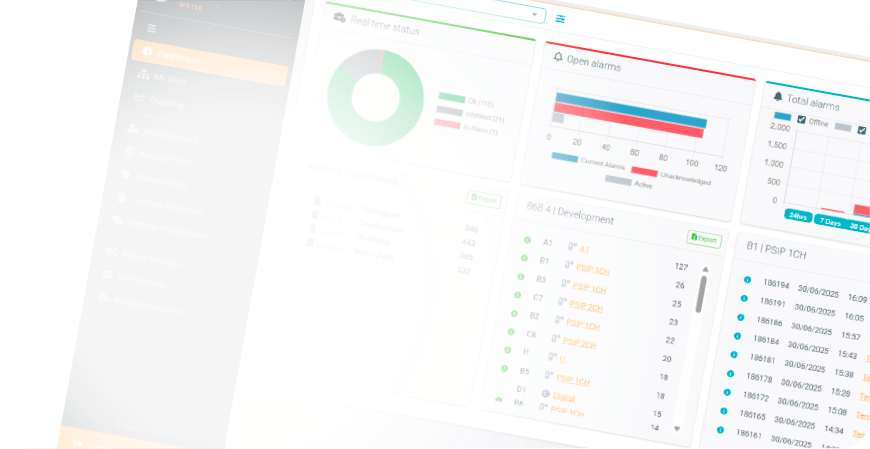

Our system seamlessly handles all compliance data capture, recording every sensor reading, temperature change, alert, and corresponding action to establish a complete, tamper-proof digital history.

The monitoring system provides the high-integrity data necessary for clients to demonstrate and maintain compliance with the strictest global standards, including the pharmaceutical rigour of GDP (enforced by the MHRA and FDA) and the core safety controls of HACCP (Food & Feed).

Live Automated Monitoring

Monitor your entire logistics network from one centralised, secure platform, providing live temperature and humidity data, instant alerts, and auditable historical records.

This secure interface is complemented by a mobile application, ensuring on-site personnel have immediate access to critical data insights and the ability to execute swift corrective actions, whether they are in the storage facility or travelling between sites.

Warehouse Compliance and Validation

Achieving full GxP compliance for your storage facility requires qualified evidence. Our services include both Installation and Operational Qualification (IQ/OQ), with a key focus on warehouse temperature mapping to formally identify and validate all thermal hot and cold spots across the storage areas. We provide UKAS-accredited calibration, ensuring every sensor is traceable, accurate, and fully documented for regulatory audit defence with absolute confidence.

One Solution, Every Environment

Compliance across the warehouse and logistics sector

From Food to Pharma, every part of the warehouse and logistics sector has unique compliance and operational demands. We provide the essential services; UKAS-accredited calibration, thermal mapping, and automated monitoring systems built with the flexibility to meet these demands. We ensure product integrity and successful audit readiness across regulatory standards (HACCP, GDP, and GMP). See below how TekTroniks provides tailored, audit-ready support for your warehousing needs.

Food storage & Warehousing

GMP, BRC, and HACCP Compliance

For companies engaged in food storage, warehousing, and logistics, the mandate is absolute: maintain uncompromising integrity of the food cold chain. This necessity is governed by rigorous global standards, including HACCP, BRCGS, GMP, and often FDA 21 CFR Part 11.

The challenge isn't just maintaining temperature; it's providing continuous, verifiable, and legally defensible data that proves compliance. Failure to achieve this level of auditable control exposes the business to significant risk, from perishable product loss to regulatory action. TekTroniks addresses this operational demand directly.

We are uniquely positioned to offer the four pillars that help establish and maintain temperature compliance for food storage operations.

Automated temperature monitoring

Our system seamlessly handles all compliance data capture, recording every sensor reading, temperature change, alert, and corresponding action. This provides a complete, tamper-proof digital history that offers total confidence and clarity, proving product safety without the paperwork hassle.

System Validation (IQ/OQ/PQ)

Having a temperature monitoring system isn't enough; you need auditable proof that it is installed and operating correctly, from day one. We provide Installation and Operational Qualification (IQ/OQ) services to formally document that your system is correctly set up and working correctly. We also offer Performance Qualifications (PQ) that confirm the system continues to operate reliably over time.

Temperature Mapping

Our Temperature Mapping services scientifically characterise your warehouse or storage to accurately identify thermal performance and pinpoint critical hot and cold spots. This guarantees optimal probe placement, essential for meeting BRCGS and validation protocols.

Ongoing UKAS-Traceable Calibration

Not only must you monitor the temperature, but you also need to prove that the temperature data is accurate. Our UKAS accreditation provides the highest level of independent proof that your temperature data is accurate, reliable, and legally defensible.

In short, we provide the technical assurance necessary for the most demanding food safety environments, turning regulatory complexity into a source of operational advantage.

Your Questions Answered

Warehouse and Logistics Temperature Compliance - FAQs

Navigating complex GMP and GDP compliance can raise specific questions about validation, system integrity, and accredited services. We have compiled a list of Frequently Asked Questions to provide quick, authoritative answers on everything from UKAS accredited calibration and thermal mapping to the long-term data integrity and installation of our monitoring solutions across your logistics chain. If you do not find the answer you are looking for, please contact our expert support team directly.

Get in touch

If you’d like to find out more about how Tek-Troniks can support your business, or have any questions about our services, we’d be happy to hear from you. You can reach us by phone, email, via the contact form, or through our social channels.

Office Address

Tek Troniks Limited

Unit 21, Manvers Business Park,

High Hazles Rd, Cotgrave,

Nottingham, NG12 3GZ

Site visits are by appointment only

Contact Us

Case Studies

Proven solutions for warehouse and logistics compliance

See how TekTroniks has helped leaders across logistics and warehousing to achieve stringent GDP compliance. Our case studies demonstrate the real-world impact of our intelligent monitoring systems and accredited services on critical cold chain processes like temperature-controlled storage and thermal validation (Temperature Mapping).